Rampley & Co Silk: A Journey to Create the Perfect Luxury Accessory

In creating luxurious silk accessories, working with the finest quality silk is clearly a critical factor in the overall quality of the final product. We have therefore devoted a lot of our energies to finding the perfect weight and weave for our pocket squares and scarves which is a very fine mulberry silk twill with 100% silk filament.

This gives our products the beautiful soft feel that people associate with high-quality silk products while allowing the design to bleed through evenly on both sides, which we feel is the hallmark of a top quality accessory. Below we’ve laid out how our silk is produced and printed to create our luxurious silk accessories.

Preparing The Silk

Firstly, the skeins of raw silk are categorised by colour, size, and quantity and then soaked in warm water mixed with oil or soap to soften the sericin before being dried.

As the silk filaments are reeled onto bobbins, they are twisted in a particular manner to achieve a certain texture of yarn. For instance, "singles" consist of several filaments which are twisted together in one direction. For our silk squares and scarves, they are turned tightly to create a sheer fabric which is the hallmark of soft silk products.

The silk yarn is then put through rollers to make the width more uniform. It is then inspected and weighed to ensure the final product is of a consistently high standard.

Our Unique Printing and Finishing Process

To achieve the distinctive softness and shine of silk, the remaining sericin in the silk must be removed from the yarn by soaking it in warm soapy water. This process known as 'degumming' decreases the weight of the yarn by as much as 25%.

Next, we coat the silk twill through a bath with rollers that irons and dries the fabric as it goes through. This coating process ensures that the acid inks print onto the cloth as optimally as possible.

The cloth is then weft straightened, a process where the fabric goes through a rolling machine to ensure that the warp threads (vertical threads) and weft (horizontal threads) are running perpendicular to each to create a straight piece of fabric ready for printing.

The silk cloth is then printed, which depending on the design is either screen printed or digitally printed, which we go into in more detail below. The final part of this stage of the process is steaming the cloth.

The combination of the chemicals from the coating, the speciality inks used and then the steaming process fixes the inks to the silk. The silk is then washed and we add products to the water which wash away any excess inks and fix the inks permanently. At this stage, we add a special recipe of softeners to finish the cloth.

The silk cloth then has a final weft straighten before being cut, hand rolled and sewn to complete the finished pocket square or scarf.

The Weight and Type of Silk

We have tested a number of silk weights in order to get the perfect weight for our pocket squares and scarves. Firstly, the weight of the silk determines how the fabric performs as a fashion accessory. Too light, and the silk is not heavy enough to have any sort of structure, so will not support more prominent folds for pocket squares and will drape limply with scarves.

If however the silk it too heavy, the ink cannot penetrate right through the silk which leaves a prominent design on one side, but a washed out pattern on the back. It is our opinion that the hallmark of a premium silk product is one where the design is almost as sharp and vibrant on the back as it is on the front. Particularly as having the design on both sides means you are not limited in your fold choices for pocket squares or how it is tied with scarves.

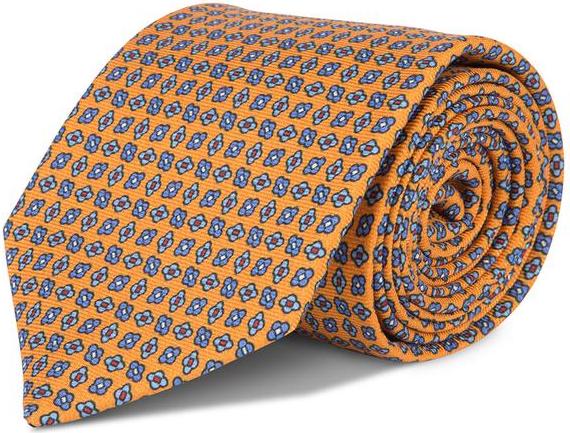

Our Silk Ties

For our handmade silk ties it was important to have the beautiful soft finish of silk, but also having a lustre that the unique limestone water that Macclesfield in the north of England is famed for. The patterns on our ties are created by screen printing the silk, a process that has been perfected in the UK over two hundred years.

Each tie is hand cut, tipped and sewn together. A woolen lining is then placed into the tie and the hand slipper then pins along the tie folding the fabric onto the lining and creating an even seam along the length of the tie. Starting at the narrow end, a stretch loop is added while slipping along the tie. The stretch loop is one continuous piece of thread used to slip the tie without joins. This allows the fabric movement when worn and the stretch loop ensures more flexibility. This is unique to a handmade tie.

Screen Printing vs Digital Printing

We use both screen printing and digital printing with our silk products, and the choice of which one to use comes down to the design of the product itself.

We do love the history and craftsmanship that goes into screen printing which originated in China more than 1000 years ago before being introduced to Europe in the late 18th century. However, due to the nature of the screen printing process, you can only work with a limited number of inks, while the design can’t be overly intricate. Digital printing means we can literally have hundreds of colours and produce extremely fine detail that are the hallmarks of many of the works we use in our products.

Digital printing, as you would expect, uses a more advanced type of printer that is able to print directly onto fabric, with exquisite detail and myriad colours.

The Process of Screen Printing

Screen printing is an extremely popular printing technique, whereby a piece of mesh is used to transfer ink onto fabric or other materials. The mesh is most commonly made from polyester, silk, or nylon, and is mounted on a wooden or aluminium frame, creating a screen.

Images and patterns can be blocked out of this screen using block stencils, these are printed negative images on paper or plastic. The images are placed on the screen and undergo a pre-printing process. An emulsion is scraped across the screen and then dried. This then allows for the emulsion to be burnt away in an exposure unit, leaving the perfect shape of the stencil.

The screen is then placed over the substrate, ready for printing. Ink is placed on the top of the screen and spread out using a squeegee. The squeegee is vital to the process as it evenly distributes the ink. A squeegee is essentially a rubber blade, the same width as the frame, which can easily be moved up and down.

The area of the screen which has been burnt out or unblocked is where the ink will pass through, straight onto the substrate. If more than one colour is required for a specific print then they must be printed through on different screens, to prevent colours mixing.

Multicoloured designs tend to use wet techniques to prevent colours drying whilst on the press, whilst more graphic designs are given time to dry. The most common means of developing stencils for screen printing is through online software.

In recent years, new presses have been rapidly produced, with some press machines producing up to over 2,000 products an hour. Arguably one of the most famous screen print artists is Andy Warhol, with his images of Campbell’s soup from 1966, and Marilyn Monroe from 1967. More information on the process of screen printing can be found on Wikipedia here: Screen printing

The History of Screen Printing

It is believed that the first method of screen printing was developed in China under the Song Dynasty (960-1279) and eventually crept over into European textiles in the 18th century. Japan and other Asian countries adopted the style of printed and combined it with methods of block printing.

Silk mesh only became widely available in Europe however in the 19th century. At first, most used screen printing for developing vibrant patterns for fabrics and wallpapers. In 1907, Samuel Simon patented screen printing in England. Western silk screen printers developed some large businesses from this and tried to be as exclusive as possible, hiding techniques and patterns from other businesses.

As the 20th century went on, people began to experiment with different chemicals and light sources as means of producing different and interesting prints. Radio-reactive stencils were tested as well as a wide range of chemicals by Roy Beck, Charles Peter, and Edward Owens, 3 men who would later revolutionize screen printing through their work.

They successfully managed to introduce photo-imaged stencils to the forefront of the textile industry, even though it did take many years for the process to be widely accepted. As the years went on during the 20th century, safer methods of silk printing were developed, with the decreasing usage of toxic or hazardous materials.

Screen printing also developed during the century as more and more people began to adopt the method, such as artists. The Serigraphic Society was set up in the 1930s and coined the term ‘serigraphy' as a means of differentiating between the artistic process of screen printing and the manufacturing process for goods.

The History of Screen Printing in Macclesfield and its Importance

Macclesfield holds closer ties to the silk industry than one would initially imagine. Cheshire, a county in the North West of England, is home to Congleton, Bollington, Stockport, and Macclesfield, 4 towns which have a long history of silk weaving from the 1600s.

Macclesfield was famous for its silk buttons manufacturers and in the 1700s its water-driven mills. The Mottershead family ran the early silk button trade in Macclesfield and Charles Roe built the first button mill in 1743.

By 1761, this mill was employing 350 people, and subsequently, various other mills popped up across the town. These new workhouses enabled Macclesfield to prosper, with wages on the up and longer hours for workers. Demand for mills increased whilst Britain was at war with France but as the war ended, there was a sharp decline, meaning Roe was forced to sell his business.

In 1790, the weaving of silk was introduced to Macclesfield and at the start of the 19th century, a boom saw 26 mills established. By 1832 this number had reached 71, making Macclesfield the world’s biggest producer of finished silk.

French revolutionaries took it upon themselves to ban the production of silk in France, thus areas like Macclesfield could flourish, enabling most of the population of the town to live off its success. Under Napoleon's leadership, however, silk was re-embraced in France thus Macclesfield started to lose out…not for long though as savvy businessmen took their ideas and methods abroad.

William Ryle II took his business to New Jersey in the United States and made a fortune of $25million. Silk printing became successful in Macclesfield in the 1820s and a century later the Brocklehurst Whiston Amalgamated was formed in 1929, which finished fabrics, printed on wooden blocks, and used hand operated silk machines.

By 1900, they had 90,000 hand printing blocks, without question the largest sum in all of Europe. Macclesfield still holds great importance to the silk industry, with the Macclesfield Silk Heritage Trust, established in 1987, championing the history of Macclesfield and its history with silk.

Conclusion

In summary, we pride ourselves on producing the finest silk accessories. By paying close attention to the quality and weight, we can develop silk products that display vibrant designs on both sides, while also retaining the soft feel that silk is so famed for.